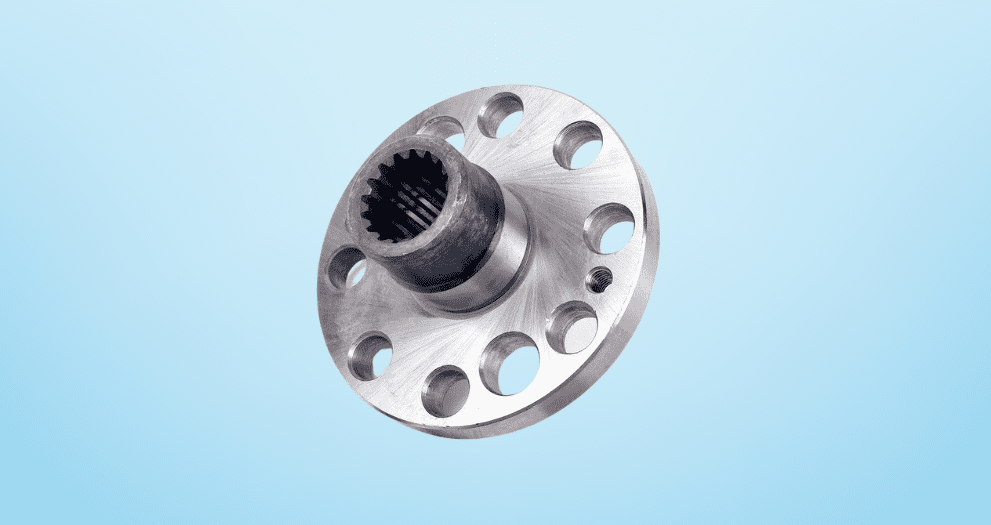

Britex, a Leading Manufacturer of Flanges, Stainless Steel Flanges, and Forged Machined Flanges in India. The company Excels in Manufacturing M.s, S.s, Forged C.s & Alloy Steel Flanges, Adhering to Standards Such as Ansi B16.5, ANSI 16.47, B.s – 4504, Din, Is:6392, Api 590, Awwa, and Customized Client Specifications.

Flanges, Essential Steel Components Facilitating Pipe Connections or Linking Pipes to Various Equipment, Are Available in Diverse Types to Meet Specific Application Requirements and Other Considerations.

Britex Employs a Meticulous Manufacturing Process Involving Heating, Forging, and Rigorous Testing to Create Flanges That Adhere to Customer Specifications. The company’s Commitment Extends to Delivering Products with Exceptional Precision and the Highest Quality, Ensured Through Thorough Testing and Certification Procedures.

In the Oil and Gas Industry, commonly used Flanges include Weld Neck Flanges, Slip-on Flanges, Lap Joint Flanges, Blind Flanges, Forged Machined Flanges, Socket Weld Flanges, Stainless Steel Flanges Screwed, and Orifice.

Flanges are essential components in any piping system, acting as the connectors between pipes, valves, pumps, and other equipment. They provide a secure and leak-proof connection, ensuring the efficient and safe flow of liquids, gases, or even slurries.

Types, Materials, and Applications of Flanges

Flanges come in a wide variety of types, materials, and pressure ratings to suit various industrial applications. Here’s a breakdown of some key aspects to consider:

Types of Flanges:

- Weld Neck Flange: The industry standard for high-pressure and high-temperature applications. Offers excellent strength due to its tapered neck that merges smoothly with the pipe.

- Slip-On Flange: A cost-effective option for lower pressure applications. Slides over the pipe end and is welded to the pipe’s outer diameter.

- Socket Weld Flange: Similar to a slip-on flange but with a smaller inner diameter that the pipe inserts into for a strong weld. Suitable for moderate pressure applications.

- Threaded Flange: Utilizes threads for connection, making it ideal for easy assembly and disassembly in low-pressure systems.

- Blind Flange: A solid disc flange used to seal off the end of a pipeline or isolate equipment for maintenance.

Flange Materials:

- Carbon Steel: The most common and cost-effective option for general-purpose applications.

- Stainless Steel: Offers superior corrosion resistance, making it ideal for harsh environments or applications involving corrosive fluids.

- Alloy Steel: Provides high strength and resistance to extreme temperatures, suitable for high-pressure systems or those handling high-temperature fluids.

- Flange Applications:

- Chemical Processing Plants: Stainless steel and alloy steel flanges are commonly used to handle corrosive chemicals and withstand high pressures and temperatures.

- Oil and Gas Industry: Flanges play a crucial role in pipelines transporting oil, gas, and refined products, requiring high-pressure and corrosion-resistant materials.

- Power Generation: Flanges are essential for connecting pipes in power plants, often made of high-temperature resistant alloys to handle steam and other fluids.

- Water Treatment Facilities: Flanges ensure secure connections in water treatment systems, with materials chosen based on pressure requirements and potential contaminant exposure.

Benefits of Using Flanges:

- Leak-Proof Connections: The bolted design of flanges creates a secure and reliable seal, preventing leaks and ensuring safe operation of the piping system.

- Versatility: The wide variety of flange types, materials, and pressure ratings allows for customization to meet the specific needs of each application.

- Easy Maintenance: Flanged connections can be easily disassembled for inspection, cleaning, or replacement of components, minimizing downtime.

- High Strength and Durability: Flanges are built to withstand high pressures and temperatures, ensuring the long-term integrity of the piping system.

Choosing the Right Flange for Your Needs:

Selecting the appropriate flange requires considering several factors:

- Pressure Rating: The flange needs to be able to handle the maximum pressure within the system.

- Temperature: The material should be suitable for the operating temperature of the fluids being transported.

- Fluid Compatibility: The flange material must be resistant to corrosion from the fluids it will come into contact with.

- Application: Consider factors like ease of assembly, maintenance requirements, and overall system design.

Industries We Serve

- Oil and Gas Industry:

- Water Treatment Plants:

- Chemical Processing:

- Power Generation

Our Customers