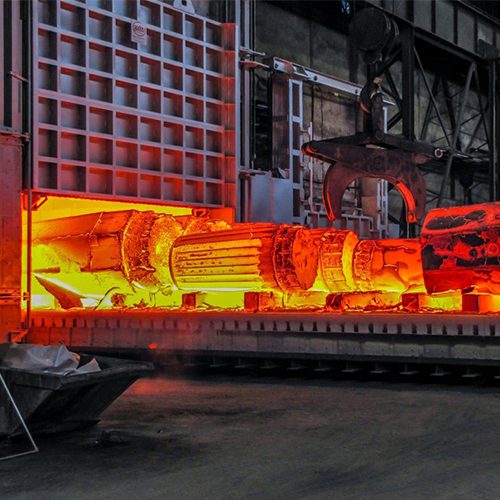

Heat Treatment

Heat Treatment is the process of heating metal without letting it reach its molten, or melting, stage, and then cooling the metal in a controlled way to select desired mechanical properties. Heat treatment is used to either make metal stronger or more malleable, more resistant to abrasion or more ductile

The following are the heat treatment processes carried out by Britex for depending upon the grade:

- Normalizing involves heating the steel to an elevated temperature, followed by slow cooling to room temperature. The heating and slow cooling changes the microstructure of the steel. The main purpose of normalizing is to refine grain size.

- Annealing involves heating a metal to a specific temperature and then cooling at a rate that will produce a refined microstructure. The main advantages of annealing are improving the workability of a material, increasing toughness, reducing hardness and increasing the ductility and machinability of a metal.

- Quenching involves heating the metal to a temperature greater than that of normal conditions, typically somewhere above its recrystallization temperature but below its melting temperature. Quenching involves the rapid cooling of a metal using quenching mediums such as water , oil, etc.

- Hardening involves heating the metal above the normalizing temperature, holding at this temperature for one hour per inch of thickness cooling at a rate fast enough to allow the material to transform to a much harder and stronger structure. The process is generally followed by tempering.

- Tempering involves heating the metal to a high temperature, though below the melting point, then cooling it, usually in air. The process has the effect of toughening of metal by reducing brittleness and reducing internal stresses thus improving the characteristics of steel.

- Stress Relieving involves heating the metal to a predetermined followed by cooling in air. The primary purpose is to relieve stresses that have been absorbed by the metal from process of forging.