Valves are an essential component in many industrial and commercial processes. They control the flow of liquids and gases, ensuring the safe and efficient operation of equipment. Many different types of valves are available, each designed for specific applications and requirements.

Forged valves and ball valves are two of the most common types of valves used in industrial and commercial systems. Both types of valves have their own unique advantages, but customizing your valves to meet your specific needs can take your operations to the next level.

Here is a closer look at these two types of valves and why customizing them can be beneficial:

Forged Valves

The forging process is used to create a forged valve. It involves heating metal until it becomes soft and then shaping it into the desired shape with mechanical forces. Laps, cold shuts, cracks, and inclusions are forging defects.

Most of the time, high-grade, small pipelines use forged valves. They are more expensive than casting-based ones. For large sizes, forging is usually a better option because large castings can cause more leak paths. For applications requiring high temperatures, forged valves are ideal. They are stronger than other types of valves and less susceptible to thermal fatigue.

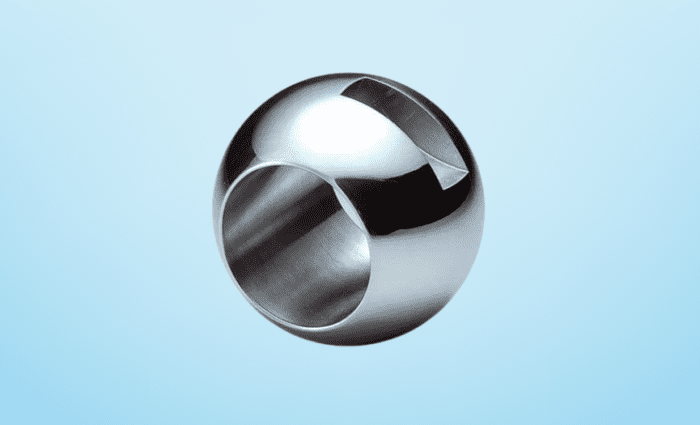

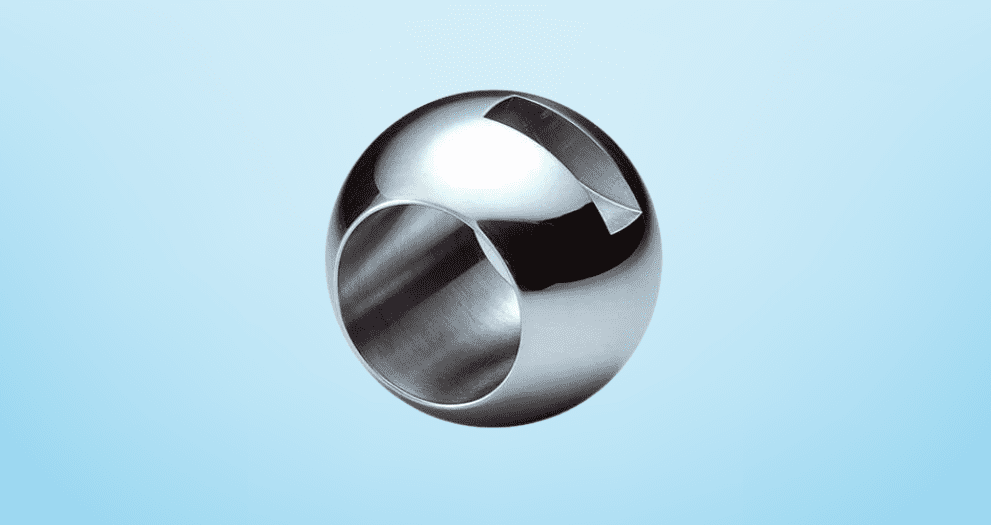

Ball Valves

Ball valves are simple, reliable, and efficient valves that use a ball to control fluid flow. They are commonly used in applications where quick and easy flow control is needed, such as in pipelines or process control systems.

A ball valve is a type of quarter-turn valve that controls the flow with a drilled-through pivoting ball. Fluids and gases can pass through the hole if it is in line with the flow direction. Alternately, when the ball is turned 90 degrees, the flow completely stops. The valve’s status can be seen by looking at the handle in either case. Open means that the handle is parallel to the valve. In contrast, the valve is closed when the handle is perpendicular.

Customized Forged Valves

Customized forged valves can help you get the most out of your equipment and systems. For example, you can choose a customized valve design that is specifically suited for your application and operating conditions. This can improve the valve’s performance, durability, and efficiency.

Whether you choose forged valves or ball valves, customizing them to meet your specific needs can greatly improve their performance, efficiency, and reliability. By taking the time to find the right manufacturer, you can ensure that your operations run smoothly and efficiently for years to come. Depending on the requirements of our clients, Britex Engineering manufactures both standard components for valves and custom components. To ensure that they meet the highest quality standards, each of our valve components is subjected to stringent testing.

Control Valves, Butterfly Valves, Ball Valves, Customized Forged Valves, Check Valves, and Globe Valves are all common types of valves utilized in the oil and gas industry. Depending on your specific requirements, our experts can assist you in selecting the best Valve Components.