Flanges are an integral component in many industries, including oil and gas, chemical and petrochemical, power generation, water and wastewater treatment, shipbuilding and marine, and construction. Understanding flanges, their types, applications, and characteristics can significantly enhance operational efficiency and safety. This comprehensive guide will walk you through everything you need to know about flanges.

What is a Flange?

A flange is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It provides easy access for cleaning, inspection, or modification. Flanges are typically welded or screwed into the system and then joined with bolts.

What is a Flange Used For?

Flanges serve several critical functions:

- Connection: They connect different components such as pipes, valves, and pumps.

- Maintenance: Flanges allow for easy disassembly, making it simpler to clean, inspect, or replace system components.

- Pressure Containment: They help maintain the integrity of the system by containing pressure within.

- Customization: Flanges can be customized to fit specific requirements, making them versatile for various applications.

What Are the Types of Flanges?

Flanges come in various types, each designed for specific applications:

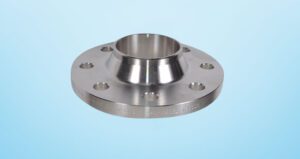

- Weld Neck Flange: Ideal for high-pressure applications, these flanges are welded to the pipe.

- Slip-On Flange: Easier to install, they slip over the pipe and are then welded.

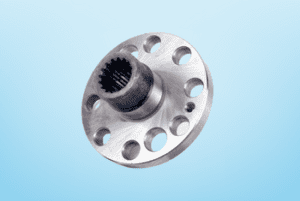

- Socket Weld Flange: Used for smaller sizes and high-pressure applications, these are welded on the outer surface.

- Threaded Flange: These flanges are screwed onto the pipe, suitable for low-pressure and non-critical applications.

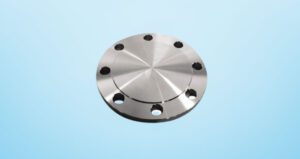

- Blind Flange: Used to close the end of a piping system, these flanges are useful for maintenance.

- Lap Joint Flange: These work with a stub end and are usually used in systems that require frequent dismantling.

What is an Example of a Flange?

In the oil and gas industry, weld neck flanges are commonly used to connect pipelines transporting high-pressure fluids. Their design ensures a robust connection that can withstand extreme conditions, making them indispensable in this field.

What is a Flange on the Body?

In anatomical terms, a “flange” refers to a projecting flat rib or rim used for attachment, such as those found in bones or other structures. However, in the context of this guide, we focus solely on industrial flanges.

Characteristics of Flanges

Flanges have several key characteristics:

- Material: Flanges are made from various materials like stainless steel, carbon steel, and alloy steel to suit different applications.

- Pressure Ratings: They come with different pressure ratings, ranging from 150 psi to 2500 psi, to handle varying levels of pressure.

- Face Types: They have different face types (e.g., raised face, flat face, ring-type joint) that affect how they seal with other components.

- Coating and Finishing: Coatings such as galvanization or epoxy are used to enhance durability and resistance to corrosion.

How Does Flange Connection Work?

Flange connections involve several steps:

- Alignment: Ensuring the flanges are correctly aligned to avoid stress on the piping system.

- Gasket Placement: A gasket is placed between the flanges to provide a seal.

- Bolting: Bolts are inserted and tightened to specified torque values to ensure a leak-proof connection.

- Inspection: The connection is inspected for alignment, gasket seating, and bolt tension.

Common Types of Flanges and Their Uses

Weld Neck Flange

- Use: High-pressure systems in oil and gas, chemical processing

- Feature: Long tapered hub for stress distribution

Slip On Flange

- Use: Low-pressure applications

- Feature: Easy installation

Blind Flange

- Use: Closing the end of piping systems

- Feature: No bore, solid disk

Threaded Flange

- Use: Low-pressure, non-critical applications

- Feature: Screwed onto the pipe

Different Faces of a Flange to Connect

- Raised Face (RF): Commonly used to increase the pressure containment capability.

- Flat Face (FF): Used when the flange is bolted to a casting.

- Ring-Type Joint (RTJ): A metal ring is compressed into a hexagonal groove to create a leak-proof seal.

Flange Dimensions and Considerations for Ensuring the Right Sizes

Flange dimensions include:

- Diameter: Ensure it matches the pipe size.

- Thickness: Determines pressure handling capacity.

- Bolt Circle Diameter: Important for bolting flanges together.

- Gasket Surface Area: Affects the sealing efficacy.

Selecting the right size involves considering the operational conditions, such as pressure, temperature, and the type of fluid being transported.

Flange Standards and Markings

Flanges adhere to various standards:

- ANSI/ASME B16.5: Covers sizes from 1/2″ to 24″

- API 605: Covers larger sizes

- DIN: European standard

Markings on flanges typically include the manufacturer’s name, material, size, pressure rating, and heat number.

Machining Process of Flange Parts

The machining process involves:

- Cutting: Raw material is cut to the desired size.

- Forging: Material is heated and shaped.

- Milling and Drilling: Holes for bolts are drilled.

- Facing: The surface is machined to ensure a smooth, flat finish.

- Inspection: Ensures the flange meets specified dimensions and quality.

What Materials Are Ideal for Making Flanges?

Materials commonly used include:

- Stainless Steel: Resistant to corrosion, ideal for chemical and marine applications.

- Carbon Steel: Cost-effective, suitable for general-purpose applications.

- Alloy Steel: Enhanced mechanical properties for high-temperature and high-pressure applications.

- Plastic and Composite Materials: Used in low-pressure applications where corrosion resistance is crucial.

Conclusion

Understanding flanges and their applications is crucial for optimizing piping systems across various industries. From connection and maintenance to pressure containment and customization, flanges play a pivotal role in ensuring operational efficiency and safety. By incorporating the right type of flange made from suitable materials and adhering to industry standards, businesses can achieve significant improvements in their workflow and reliability.